Measuring the Benefits of a Product Launch Portal

ROI WHITE PAPER

In an ever more competitive global market, product launch is critical as manufacturers strive to grow market share and revenue, defend their positions in existing markets, and improve customer experiences.

Timely launches of high-quality products can be threatened by internal organizational silos and misalignment across the supply chain, inconsistent or undefined processes, and disparate or missing data sources and systems. These threats can impact time-to-market, costs, and performance quality.

As many manufacturers struggle with internal siloes, collaboration with increasingly complex supplier networks has become a critical challenge in meeting product launch objectives.

This paper explores the inherent risk of the critical partnerships companies form with their suppliers, particularly the sources and impacts of supply chain disruptions and cost creep. A product launch portal provides insight and creates impact across an organization, and LiveSource has developed a methodology to calculate and predict the quantitative impact of a launch portal by taking into account both direct and hidden costs throughout the organization.

By implementing a product launch portal, complex manufacturers can build trust through transparency, and increase agility and stability as part of their broader business continuity plans.

“ While manufacturers invest heavily in NPI (new product introduction), the median manufacturer gets a failing grade. A startling 44% of new products fail to meet all or even most NPI success criteria.”

— LNS Research, Supplier Management in NPI: Three Steps to Better NPI, Quality, and Manufacturing Performance, 2019

Suppliers: Critical Partners, Inherent Risk

Suppliers are critical partners for growing business capacity and reach, as well as driving an organization’s agility and innovation. By their nature, however, suppliers are associated with risks that can erode your organization’s value by increasing costs. In particular, supply chain disruptions can lead to financial ramifications related to delayed deliveries. In some cases, if the end customer simply perceives a problem, it could lead to many of those same financial ramifications, even when actual delivery remains on schedule.

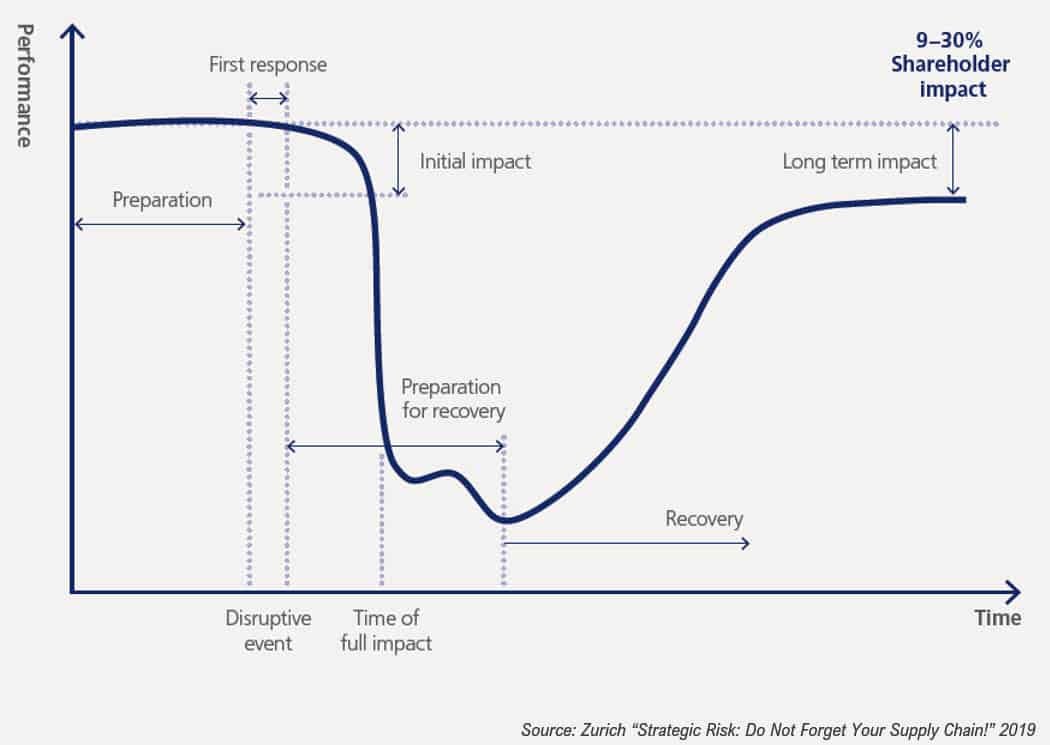

According to research by Zurich Insurance Group (Strategic Risk: Do Not Forget Your Supply Chain!, 2019), “Companies can be simultaneously impacted by decreased sales and brand damage, while incurring significant extra expenses during recovery times following a business interruption. Historically, supply chain disruptions can lead to an average of 9 percent lower sales and 11 percent higher costs, and many companies with extended interruptions never recover.”

A major disruption can be catastrophic for a business, but disruptions are shockingly common. Over 85% of manufacturers report at least one supply chain disruption per year; more than 50% of manufacturers report two or more disruptions.

Not all supplier-related risks are external – internal data related to suppliers can create risk. Traditionally, information is kept in disparate systems, from enterprise systems such as ERPs to spreadsheets to email; historical and real-time data is often siloed or duplicated throughout the disparate systems, as well. With multiple “sources of truth,” outdated, non-standardized data, multiple collection points and methods, it is difficult to have a clear, accurate picture of the organization’s supplier landscape; this can have some surprising impacts on the business, many of them strategic.

For example, when businesses lack access to standardized historical data, they’re likely lose a competitive edge due to cost creep, generating pricing based on a formula – perhaps faulty assumptions of rising supplier costs – instead of data. Without data related to the evolution of costs due to changes in components, material, the economy, and other factors to back up decisions, price quotes can be difficult to defend when a customer pushes back. This lack of data also, certainly, puts the company at a disadvantage when negotiating with its suppliers.

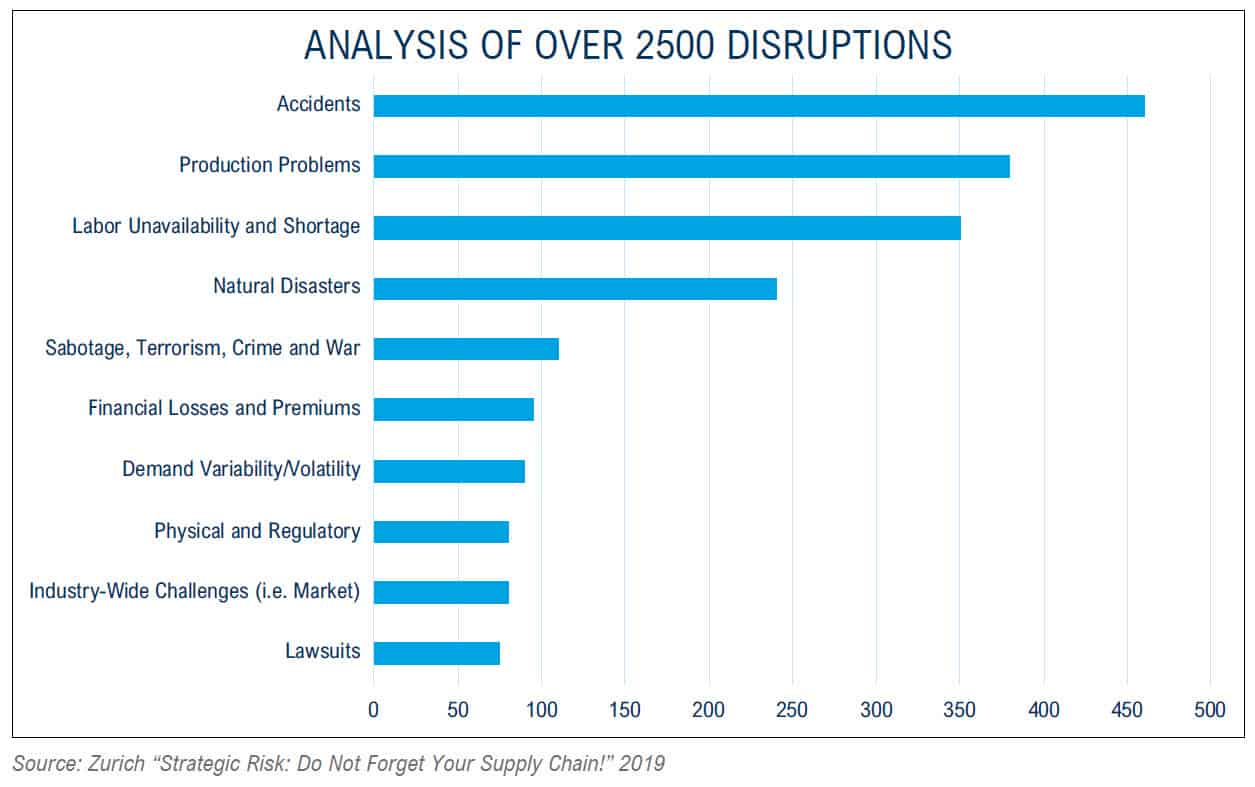

Sources & Impacts of Supply Chain Disruption

The Zurich study found that IT and communication issues present the primary supplier risk, followed by transportation problems, labor unavailability, and regulatory changes. Surprisingly, while natural disaster was a key cause of supply chain disruption, many interruptions were not directly tied to the physical damage but to secondary issues such as power outages, infrastructure problems, labor and ingress/egress challenges.

In addition to these supplier risks, we have found the root cause of most supplier challenges are interrelated (and fundamentally related to communication), ranging from Bill of Materials (BOM) changes to rogue activities, supplier certification issues, tooling, and quality issues. BOM changes are frequent during the launch phase, and miscommunication related to those changes can lead to missed launch dates, higher costs, and loss of revenue, leaving the company’s reputation damaged. Miscommunication can also delay the completion of a Production Part Approval Process (PPAP), which can impact cash flow because the associated tooling will not be reimbursed by the customer until the PPAP is complete. Quality issues may result from tools running over capacity limitations, or past the quoted lifetime of the tool. Another consequence is parts nonconformance, which may cause shutdowns, warranty issues and recalls.

These disruptive events have negative consequences on a company’s long-term viability. Beyond penalties assessed by customers, a major disruption results in an average 25% reduction in stock price over two years (reputation), a 9% drop in revenue, and an 11% increase in costs. More: supply chain disruptions impact business relationships upstream and downstream. When a supplier creates a crisis for a customer, the customer may re-evaluate the value of the relationship. They may impose financial penalties, or they may choose another supplier entirely when awarding future contracts.

Internally, even minor disruptions take employees away from current projects, contributing to future issues and delays. If it happens regularly, firefighting lowers employee morale and is directly tied to increased turnover. Supplier challenges often cause an erosion of trust between Purchasing and Sales teams. Better intelligence about the supply chain can positively transform an entire organization.

Beyond uncovering opportunities for efficiencies, a launch portal for new product introductions mitigates risk and delivers broad financial and reputational return on investment. By leveraging historical, real-time, and forecast data, decision makers can anticipate disruptions and speed recovery time in the event of an incident. They are better informed, more agile, and empowered to be proactive.

How Supplier Relationship Management Delivers Value

Gathering data from disparate sources and standardizing it, a product launch portal provides great insights to drive better decision making that leads to process improvements. A launch portal delivers value in four key areas: risk, revenue, reputation, and cost.

IDENTIFY, MITIGATE AND MANAGE RISK WITH ANALYTICS

As we explored above, suppliers inherently introduce risk into a business. An organization is often so heavily reliant on just-in-time delivery that even a minor disruption, from the supplier’s perspective, can become a major crisis. A launch portal taps into disparate systems, applying analytics to uncover insights and patterns in supplier behavior. Awareness of these patterns can better equip companies to minimize disruptions. For example, underperforming suppliers can be flagged, so either corrective action can be taken or other suppliers can be sourced before a crisis develops. Additionally, supply chain analytics make it easier to manage supplier financial, social, and regulatory compliance, by monitoring supplier activities and automating notification when they fall out of compliance. Ultimately this all positions companies to avoid disruptions and shorten the recovery period when a disruption does occur.

PROTECT CURRENT AND FUTURE REVENUE

A product launch portal helps organizations discover opportunities to protect and maximize current and future revenue. With better information about all aspects of the supply chain, companies can generate more accurate and competitive quotes; this helps ensure they’re pricing to win contracts while preserving margins. In addition to supplier disruption, demonstrated tooling capacity can highlight potential future production challenges, ensuring future on-time delivery at the contracted price. Also, insights about suppliers, production, packaging, and transportation can lead to innovation: the ability to engage in what-if scenarios encourages all parties to more confidently introduce new approaches and solutions that can drive revenue.

PROTECT AND IMPROVE REPUTATION

The benefits of a product launch portal go beyond avoiding the disruptions addressed earlier: systemic optimization drives employee engagement and increases morale, particularly through the reduction of firefighting events. Real-time data analysis paired with well-informed planning can help ensure on-time program launches. In production, analytics can detect variances, which should help minimize non-conformances that lead to late deliveries or returns. Further, as customers increasingly choose to work with companies which work to minimize their environmental impact and strive to engage in ethical practices, supply chain business networks empower companies to track and validate their Environmental, Social and Governance (ESG) initiatives.

REDUCE COSTS

Cost savings are the benefits most commonly associated with product launch portals. When historical and real-time supply chain data has been standardized so an organization can leverage robust analytics on it, opportunities for cost savings can present themselves in aspects of the business they may not have considered or been able to know about previously. With more accurate information, companies can avoid cost increases, minimize expedited activities and the costs related to them, and manage rogue launch activities. This encourages supplier engagement and transparency, which can drive innovation that streamlines costs, as well.

Quantifying the Value

When an organization is seeking to mitigate risk, drive revenue, protect their reputation, and reduce costs, product launch portals can deliver measurable results. Stakeholders often must demonstrate the tangible return on investment in order to build a business case that justifies the resources required to implement this sort of new business system. LiveSource has developed a methodology to calculate and predict the quantitative impact of a product launch portal, one that accounts for both the direct and the hidden costs related to operations.

The methodology of determining ROI comprises calculations of data points based on industry standards as well as organization-specific variables – a relatively simple exercise of inputting about two dozen business and financial details and then identifying what common opportunities for cost savings and avoidance are currently in place. Among the factors contributing to the ROI calculation are hours spent managing suppliers, disruption costs and recovery time, sourcing requirements, Contingent Business Interruption (CBI) coverage, sales, and shareholder value. The values of each of these can be adjusted to accommodate different scenarios.

The results, financial impacts annually over each of three years, are presented as a dashboard and in a table of line items. In particular, the calculator brings opportunities for cost savings and for cost prevention to the forefront. Among the cost savings that can be projected are the benefits resulting from automation of supplier management data (including the time savings related to inputting and updating supplier information), retired systems, reduction of minor supply chain disruptions, sourcing opportunity cost reductions, and reduction of CBI insurance premiums through supply chain transparency. Cost prevention calculations illustrate the bottom-line impact from reduction of major crisis resolution time, prevention of sales shortfall, prevention of future lost sales, and shareholder value loss per major crisis.

Implications

The ROI calculator is a starting point from which businesses can build their own specific business case. By working with realistic variables derived from the organization’s actual operations, companies can determine the real potential financial impacts and benefits of a product launch portal.

Typically, Finance departments limit the business case driver for new systems to increasing efficiency: once implemented, a task that used to take X hours now only takes Y (and can therefore be done by fewer personnel). Cost avoidances and secondary costs are not typically considered. The exercise of calculating ROI prompts a broader understanding of secondary related costs that extend beyond the original immediate disruption, and where cost savings or avoidances could be found throughout the supply chain.

But, beyond the bottom line, the insights derived from a product launch portal have qualitative results: standardization across a unified information vocabulary, standardized data and better data visibility throughout the entire supply chain. This keeps suppliers honest, and builds more trusting partnerships with the supply base, in addition to providing more accurate and competitive quotes that have mitigated sources of price creep. This is invaluable when negotiating or resolving supplier and OEM issues. Better collaboration with suppliers leads to innovative solutions, and ultimately, a competitive advantage. This is the ultimate business case for a product launch portal.